Hi Guys,

Just wondering if someone could help me. I have installed a Dash2 with a DL1 into a rally Honda EG6 which I am nearly finished building. We built our own wiring loom for the car.

My problem is this, looking a the electrical schematic for a honda civic the three wire sendor is conected along the -ve or earth side of the electrical circuit. Now as per race technology guidelines I am going to use the regulated 5V output on the DL1 as my voltage source, back through a votage dividing circuit as per their instructions on the 'How do I ' help section and use this voltage as my input on an analogue channel on the DL1.

By using this 5V source am I not introducing a voltage and potentially the possiblity of a spark into the fuel tank. Why this worries me is that we will run very light fuel loads for sprints etc, where there would be very little fuel in the tank and a lot of vapours?

Any help, anyone could give would be appreciated as I have had no oher issues so far and think the system is good but I cant get my head around this.

Tommy.

Fuel level sensor in Honda Civic

Tap into the wiring outside of the tank. Inside should just be stock woring.

You can build your own voltage divider or this place will make you one (with slosh damping) based on your resistance specs.

http://www.ironcanyonmotorsports.com/pr ... ucts_id=38

Be sure to check the max current draw at your resistance extremes. IIRC DASH2 is limited to something like 0.25 or 0.5 amps for all regulated circuits. If you need more current, Radio Shack has little 5V regulated ICs for a couple dollars.

You can build your own voltage divider or this place will make you one (with slosh damping) based on your resistance specs.

http://www.ironcanyonmotorsports.com/pr ... ucts_id=38

Be sure to check the max current draw at your resistance extremes. IIRC DASH2 is limited to something like 0.25 or 0.5 amps for all regulated circuits. If you need more current, Radio Shack has little 5V regulated ICs for a couple dollars.

Jeremy Lucas

Fast Tech Limited - a Race Technology Dealer

Fast Tech Limited - a Race Technology Dealer

Fuel level sensor in Honda Civic

Hi Jeremy,

Thank you for your reply and your link to Ironcanyon. I think I might be over thinking this a little!! I built a voltage divider and based it on not exceeding 50mA from the DL1. I have several other sensors wired through the DL1 and back to the Dash2. I have everything ready to go but I just cant get it into my brain, as I am using the stock sensor in the tank which goes from 0-110 Ohms. My only problem is that I think there is a safety issue with bringing 5Vdc through the sensor as if the pickup point on the sensor moves away from the resistor itself under hard braking/ hard conering, is there not a possiblity that a spark could be created. I have spent nearly 18 months building this car and dont want to be sitting on a bomb!!!!

I am living outside Dublin in Ireland and there is not many of these systems used here and that means that nobody knows anything about them.

Tommy

Thank you for your reply and your link to Ironcanyon. I think I might be over thinking this a little!! I built a voltage divider and based it on not exceeding 50mA from the DL1. I have several other sensors wired through the DL1 and back to the Dash2. I have everything ready to go but I just cant get it into my brain, as I am using the stock sensor in the tank which goes from 0-110 Ohms. My only problem is that I think there is a safety issue with bringing 5Vdc through the sensor as if the pickup point on the sensor moves away from the resistor itself under hard braking/ hard conering, is there not a possiblity that a spark could be created. I have spent nearly 18 months building this car and dont want to be sitting on a bomb!!!!

I am living outside Dublin in Ireland and there is not many of these systems used here and that means that nobody knows anything about them.

Tommy

What makes you think 5V is anymore dangerous than 12v?

Your stock ECU would have also been likely using a regulated voltage for fuel level and in effect the fixed value resistor of the voltage divider circuit is internal to the ECU.

Your stock ECU would have also been likely using a regulated voltage for fuel level and in effect the fixed value resistor of the voltage divider circuit is internal to the ECU.

Jeremy Lucas

Fast Tech Limited - a Race Technology Dealer

Fast Tech Limited - a Race Technology Dealer

Fuel level sensor in Honda Civic

Sorry for being a pain in the ass Jeremy!

When I looked at the wiring configuration from the stock Honda Electrical drawing, it shows the fuel gauage itself supplied at 12v. The reference from the sensor in the tank is shown connected across the voltage dividing circuit and the frame of the car, which makes me think that there is no actual voltage or potential across the resistor.

Now my engine management system is an Omex 600 as I rewired the car completely as it for racing only and I did not need a lot of the stuff contained in the original loom so I did not use the stock ECU and the Omex is being used to control a throttle body system, but it is not supplying the fuel sensor, the DL1 is as I wanted to log fuel levels for speed events.

In my present configuration with the voltage dividing circuit I made, I have a full scale deflection of between 0.02V empty to 0.4V full but there is now 5V present from the DL1 across the resistor, and this is all that is worrying me, whereas in the stock system one side of the resistor is grounded to the chassis of the vehicle and therefore unless the ground wire breaks there is no potential for spark?

I am probably over analysing it and at those voltages the current will be so small it cant create a spark but I am just not convinced.

I think I am just going to have to connect it, pray!! and go racing see what happens!!

When I looked at the wiring configuration from the stock Honda Electrical drawing, it shows the fuel gauage itself supplied at 12v. The reference from the sensor in the tank is shown connected across the voltage dividing circuit and the frame of the car, which makes me think that there is no actual voltage or potential across the resistor.

Now my engine management system is an Omex 600 as I rewired the car completely as it for racing only and I did not need a lot of the stuff contained in the original loom so I did not use the stock ECU and the Omex is being used to control a throttle body system, but it is not supplying the fuel sensor, the DL1 is as I wanted to log fuel levels for speed events.

In my present configuration with the voltage dividing circuit I made, I have a full scale deflection of between 0.02V empty to 0.4V full but there is now 5V present from the DL1 across the resistor, and this is all that is worrying me, whereas in the stock system one side of the resistor is grounded to the chassis of the vehicle and therefore unless the ground wire breaks there is no potential for spark?

I am probably over analysing it and at those voltages the current will be so small it cant create a spark but I am just not convinced.

I think I am just going to have to connect it, pray!! and go racing see what happens!!

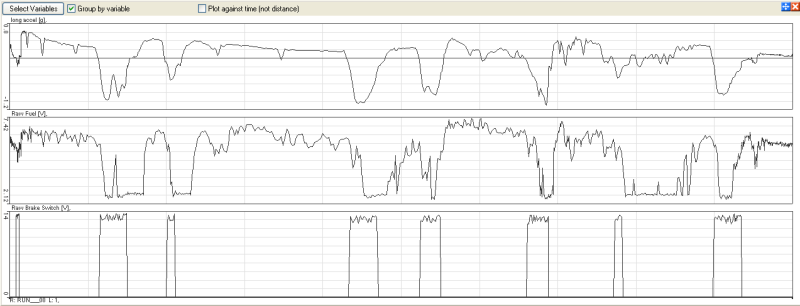

In my experience there is so much sloshing around of the fuel in a standard tank that the fuel sensor reading will be more or less useless when on track. You will need to filter the values very heavily over quite an extended period of time.

What are you really trying to measure ? fuel consumption or the level of fuel left in the tank ?

What are you really trying to measure ? fuel consumption or the level of fuel left in the tank ?

flatshift,

I have a beater Honda Civic that I use as a daily driver. Here's a link to a schematic of the fuel circuit.

http://home.comcast.net/~thedrol/images/fuel.pdf

Think of the fuel gauge as a resistor and the fuel sender as a resistive potentiometer. Point A will have 12V on it, Point B will be someplace between 12V and 0 depending on the resistance of the gauge and sender. If you create your circuit in a similar manner using 5V instead of 12V you will be even better off than what Honda did on this passenger car due to the lower voltage.

In the service manual they tell you to disconnect the connector at Point B and measure the voltage when the ignition is on. If you have 12V it is correct if not, there is a blown fuse or bad wire.

Disclaimer: This of course doesn't mean that if you do something really dumb, that you can't cause a problem.

Paul

I have a beater Honda Civic that I use as a daily driver. Here's a link to a schematic of the fuel circuit.

http://home.comcast.net/~thedrol/images/fuel.pdf

Think of the fuel gauge as a resistor and the fuel sender as a resistive potentiometer. Point A will have 12V on it, Point B will be someplace between 12V and 0 depending on the resistance of the gauge and sender. If you create your circuit in a similar manner using 5V instead of 12V you will be even better off than what Honda did on this passenger car due to the lower voltage.

In the service manual they tell you to disconnect the connector at Point B and measure the voltage when the ignition is on. If you have 12V it is correct if not, there is a blown fuse or bad wire.

Disclaimer: This of course doesn't mean that if you do something really dumb, that you can't cause a problem.

Paul

fuel level sensor

Turby wrote:In my experience there is so much sloshing around of the fuel in a standard tank that the fuel sensor reading will be more or less useless when on track. You will need to filter the values very heavily over quite an extended period of time.

What are you really trying to measure ? fuel consumption or the level of fuel left in the tank ?

Hi Turby,

Thanks for your reply. I am trying to measure fuel level in the tank in litres. The car will be used for two type of events, 1. Road racing on closed public roads of approx 20Km long. In this instance it just matters that i have enough fuel to complete the 20km so any rough indication of whats in the tank will be fine.

2. The second thing its to be used for is quarry sprints, which are 1.5km sprints on a loose surface. My class 1600cc 16v is the tightest class and I want an accurate idea of whats in the tank so that I can keep fuel level {weight} to a minimum, as sometimes 0.1s can decide results so the more accurate I can judge how much fuel is the tank before and after a run the better.

I dont care about the fuel sloshing around the tank and would not have much interest in the traces that the sensor sends to the DL1 during racing, I need an accurate reading before the race starts and after I get back to the pits.

But, and there is always a but I dont think it would be safe to connect the 5V from the DL1 across the resistor in the tank2

Dear flatshift and rest,

I have exactly the same problem and hesitation and that's why i decided to install a standard vdo meter (rheostat type 0-105 ohm on a FN2 type R model for rally application).

According to my personal opinion, no one can or should guarantee that the voltage resistor will cause no problems at the "baptised" rheostat in the fuel tank.

Of course, having an instant reading for the fuel left in the tank, as you can probably understand, is crucial for my case as well. And yes, those 5-10 more lt's on the tank, can affect results in lot of categories of racing, where weight matters.

My approach is to drive the car (of course in private or controlled roads) to the limits and measure the maximum consumption in fuel, like running in a SS.

The bottom line is that i strongly believe safety goes first.

The choice is yours.

Best regards,

A.

I have exactly the same problem and hesitation and that's why i decided to install a standard vdo meter (rheostat type 0-105 ohm on a FN2 type R model for rally application).

According to my personal opinion, no one can or should guarantee that the voltage resistor will cause no problems at the "baptised" rheostat in the fuel tank.

Of course, having an instant reading for the fuel left in the tank, as you can probably understand, is crucial for my case as well. And yes, those 5-10 more lt's on the tank, can affect results in lot of categories of racing, where weight matters.

My approach is to drive the car (of course in private or controlled roads) to the limits and measure the maximum consumption in fuel, like running in a SS.

The bottom line is that i strongly believe safety goes first.

The choice is yours.

Best regards,

A.

Fuel level sensor in Honda Civic

Well Guys,

Just a little note to let you know the present state of play. The agent I bought the Dash2 and DL1 had been on holidays. He supplied a device for the tank sensor which has no identifaction marks on it.

I got speaking to him and he told me that the device is a pull up resistor for use with resistive devices, changing the resistance of the sensor into an analogue voltage which can then be logged. I setup a sensor on the work bench and connected it as directed. The voltage across the sensor varied between 0-7vdc as the device he supplied has an inbult votage regulator from 0-8V.

When I put the multimeter across the two wires coming from the sensor, there was between 0-7v across it which I didnt think was safe.

So I made up another voltage divider, using a 1W, 1K biasing resistor in series with the tank sensor which varies from 0-110Ohms. I now have between 0 and 0.5V across the resistor between extremes on the sensor. I put an ammeter inseries with the circuit and it doesnt register any current, which I now believe to be a better job.

I calibrated the sensor using 2L increment of petrol and generated my equation from that, saved it and all seems good. It is accurate to approx .5 litre. So happy days.

Only issue is this when the car has power applied to it, sometimes the fuel reading is way off e.g. 666litres in the tank!! Switching the car off, leaving it for ten or twenty seconds and reapply power the sensor reads properly. Any ideas on what could be up here?

Just a little note to let you know the present state of play. The agent I bought the Dash2 and DL1 had been on holidays. He supplied a device for the tank sensor which has no identifaction marks on it.

I got speaking to him and he told me that the device is a pull up resistor for use with resistive devices, changing the resistance of the sensor into an analogue voltage which can then be logged. I setup a sensor on the work bench and connected it as directed. The voltage across the sensor varied between 0-7vdc as the device he supplied has an inbult votage regulator from 0-8V.

When I put the multimeter across the two wires coming from the sensor, there was between 0-7v across it which I didnt think was safe.

So I made up another voltage divider, using a 1W, 1K biasing resistor in series with the tank sensor which varies from 0-110Ohms. I now have between 0 and 0.5V across the resistor between extremes on the sensor. I put an ammeter inseries with the circuit and it doesnt register any current, which I now believe to be a better job.

I calibrated the sensor using 2L increment of petrol and generated my equation from that, saved it and all seems good. It is accurate to approx .5 litre. So happy days.

Only issue is this when the car has power applied to it, sometimes the fuel reading is way off e.g. 666litres in the tank!! Switching the car off, leaving it for ten or twenty seconds and reapply power the sensor reads properly. Any ideas on what could be up here?

-

Support

Great help from you guys. I am currently installing my hella fuel level sensor and I am looking for these information. Thank you so much!!

Return to “Sensor-related questions”

Who is online

Users browsing this forum: No registered users and 22 guests