I'm considering using Cherry GS100102 speed sensor (Hall Effect) on the front and rear of my car.

Can you mount the sensors such that the bolts used to secure the rotor to the hat trigger the sensor? I'm concerned about heat from the rotors damaging the sensors.

Also, the front rotors use stainless hardware to secure the rotor. I suspect this will not trigger the sensor. Is this correct?

speed sensor mounting location - heat?

speed sensor mounting location - heat?

Billy

98 Prelude - #27 NASA TX PT

98 Prelude - #27 NASA TX PT

I tried the GS100102s but the response voltage signal (or whatever you call it) didn't have a high enough voltage to be picked up by the DL1. I think the transistor saturates and doesn't switch properly so it won't output >5VDC from the input voltage.

I can't remember what voltage I feed the sensor. I may be 10VDC from a linear voltage regulator.

I moved to a GS100502 sensor and it worked perfectly. I mount them on the back side of the front brake rotor of my 2000 BMW M Coupe and pick up a bolt head on the back of the wheel bearing flange. My rotors run at ~1,000*F according to temp paint on the rotor face. I have not had an issue with temperature sensitivity.

The GS100502s are actually rated to a higher operating temperature. Aluminum is actually an ideal material for an auto application - assuming you don't run it in winter road salt.

I use a common grade 5 bolt on the backside of the bearing flange. The same bolt hole that is supposed to hold the rotor to the bearing face for service.

The sensors operated by detecting a change in a magnetic field - though not necessarily from a magnet - the pickup just needs to be ferrous.

Some stainless steels are magnetic, some are not. If you can stick a magnet to your bolts, then it will work. If not, you will need to find a way to fix a ferrous target to the hub.

I only use one target per revolution - at speeds higher then about 40-50mph, there is enough resolution to be accurate enough to detect ABS applications.

I can't remember what voltage I feed the sensor. I may be 10VDC from a linear voltage regulator.

I moved to a GS100502 sensor and it worked perfectly. I mount them on the back side of the front brake rotor of my 2000 BMW M Coupe and pick up a bolt head on the back of the wheel bearing flange. My rotors run at ~1,000*F according to temp paint on the rotor face. I have not had an issue with temperature sensitivity.

The GS100502s are actually rated to a higher operating temperature. Aluminum is actually an ideal material for an auto application - assuming you don't run it in winter road salt.

I use a common grade 5 bolt on the backside of the bearing flange. The same bolt hole that is supposed to hold the rotor to the bearing face for service.

The sensors operated by detecting a change in a magnetic field - though not necessarily from a magnet - the pickup just needs to be ferrous.

Some stainless steels are magnetic, some are not. If you can stick a magnet to your bolts, then it will work. If not, you will need to find a way to fix a ferrous target to the hub.

I only use one target per revolution - at speeds higher then about 40-50mph, there is enough resolution to be accurate enough to detect ABS applications.

BMW 2000 M Coupe

Great information. Thanks a bunch. The sensor you recommended is actually cheaper than the one I was planning to use. I thought they were identical except one was a stainless body and the other aluminum. I picked the stainless model since it had a higher operating temp limit.

I'll have to figure out something to trigger the sensor if the hardware I'm using is nonferrous. AIM makes an interesting magnet with an adhesive backing that can be installed on the ID of the wheel.

I'll have to figure out something to trigger the sensor if the hardware I'm using is nonferrous. AIM makes an interesting magnet with an adhesive backing that can be installed on the ID of the wheel.

Billy

98 Prelude - #27 NASA TX PT

98 Prelude - #27 NASA TX PT

The simplest way is to drill and tap a bolt in the flange.

It sounds like you have floating rotors on AL hats?

You could also replace one or two of the stainless bolts with a Grade 8 SAE or Grade 10 Metric bolt.

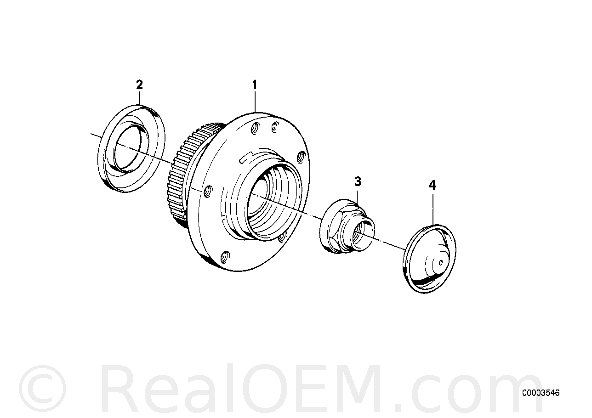

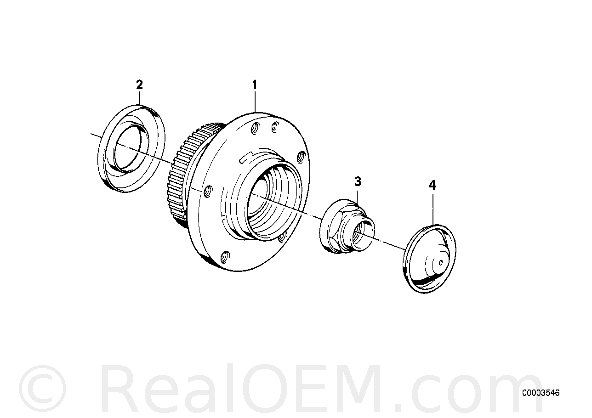

Not sure what your front bearings look like. This is a BMW bearing. The rotor mounts to the face of this flange.

The little hole that is just to the right of the stud hole at 12 o'clock is normally used to hold the face of the rotor to the bearing flange. I put a bolt on the backside of that for the pickup. I used the cooling duct backing plate to hold the sensor.

It sounds like you have floating rotors on AL hats?

You could also replace one or two of the stainless bolts with a Grade 8 SAE or Grade 10 Metric bolt.

Not sure what your front bearings look like. This is a BMW bearing. The rotor mounts to the face of this flange.

The little hole that is just to the right of the stud hole at 12 o'clock is normally used to hold the face of the rotor to the bearing flange. I put a bolt on the backside of that for the pickup. I used the cooling duct backing plate to hold the sensor.

Last edited by osborni on Thu Dec 03, 2009 5:16 pm, edited 1 time in total.

BMW 2000 M Coupe

I'm using floating rotors up front and fixed mounted rotors in the rear. Both are two piece with aluminum hats.

I think the casting for the upright may get in the way of the hub flange. The hubs on my car look very similar to the picture you've posted below, I just need to see if there is space for the sensor. If there isn't enough space, I'll replace one or two of the rotor hat bolts to trigger the sensor.

Thanks a ton for your help. I'm still in the middle of completely rewiring my car, so I won't be able to double check this for a few weeks, but I'm going to order the sensors this week.

I think the casting for the upright may get in the way of the hub flange. The hubs on my car look very similar to the picture you've posted below, I just need to see if there is space for the sensor. If there isn't enough space, I'll replace one or two of the rotor hat bolts to trigger the sensor.

Thanks a ton for your help. I'm still in the middle of completely rewiring my car, so I won't be able to double check this for a few weeks, but I'm going to order the sensors this week.

Billy

98 Prelude - #27 NASA TX PT

98 Prelude - #27 NASA TX PT

osborni,

Did you actually do what you wrote? It's contradicted by the documentation from both Cherry and RT.

Cherry documentation says that the GS series sensors cannot do sourcing output (low when nothing in front of sensor, high when ferrous object in front of sensor). GS can only do sinking output.

http://www.cherrycorp.com/english/senso ... ection.pdf

The RT docs say that the DL1 requires a sourcing signal. See:

http://www.race-technology.com/wiki/ind ... eedSensors

I think you just made me waste $150 on sensors that I cannot use and cannot return.

-Kyle

Did you actually do what you wrote? It's contradicted by the documentation from both Cherry and RT.

Cherry documentation says that the GS series sensors cannot do sourcing output (low when nothing in front of sensor, high when ferrous object in front of sensor). GS can only do sinking output.

http://www.cherrycorp.com/english/senso ... ection.pdf

The RT docs say that the DL1 requires a sourcing signal. See:

http://www.race-technology.com/wiki/ind ... eedSensors

I think you just made me waste $150 on sensors that I cannot use and cannot return.

-Kyle

Thanks osborni.

How big is the bolt that you're using as a trigger? In other what's the linear distance of the bolt that the sensor sees?

I did some calcs and, you're right, it may work. My calcs show that it should take .89ms for the bolts to pass over the sensor at 100mph.

The RT docs say that anything over .25ms will work.

Also, based on a conversation with RT in UK, they're own sensor is a sinking style.

So maybe that "sinking feeling" I had yesterday was for nothing ....

-Kyle

How big is the bolt that you're using as a trigger? In other what's the linear distance of the bolt that the sensor sees?

I did some calcs and, you're right, it may work. My calcs show that it should take .89ms for the bolts to pass over the sensor at 100mph.

The RT docs say that anything over .25ms will work.

Also, based on a conversation with RT in UK, they're own sensor is a sinking style.

So maybe that "sinking feeling" I had yesterday was for nothing ....

-Kyle

Thanks Man.

That's right where I am (wrapped around the axle).

I'm cautious because fitting these sensors will require a substantial amount of fabrication (welding to the uprights, etc).

I don't see any other sensors with a similar form factor, so if they don't work, it was all for naught.

But confirmation of your real world experience is very helpful.

-Kyle

That's right where I am (wrapped around the axle).

I'm cautious because fitting these sensors will require a substantial amount of fabrication (welding to the uprights, etc).

I don't see any other sensors with a similar form factor, so if they don't work, it was all for naught.

But confirmation of your real world experience is very helpful.

-Kyle

Return to “Sensor-related questions”

Who is online

Users browsing this forum: No registered users and 39 guests