Set up gear indicator

The DASH2 has a large gear indicator in the top right hand corner of the screen. This can be configuring by clicking on the 'Set up gear indicator' icon on the DASH2 configuration software:

If not required the gear indicator can be turned off by selecting the 'Hide' option. When used there are two ways to obtain the current gear ratio, either by calculating the value based on the current engine speed and gear speed, or by using a sensor on the gearbox or other data source such as an ECU to give the readings

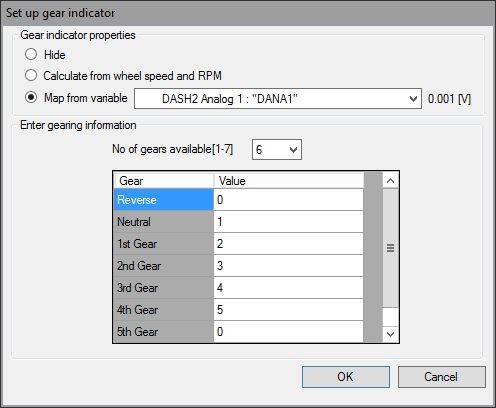

Calculate from wheel speed and RPM

With this option selected, the option box will change to show the upper and lower limits on which the gear values are calculated. These are entered in terms of km/h per 1000rpm. So if in 3rd gear a vehicle is travelling at 160km/h at 6000rpm this would be 26.67 km/h per 1000rpm. To give some leeway for slight errors in the readings upper and lower values are used, if 25 and 28 are used as upper and lower values then the display will show a value of 3 for the indicated gear any time the speed and RPM ratio is between 25 and 28km/h per 1000rpm.

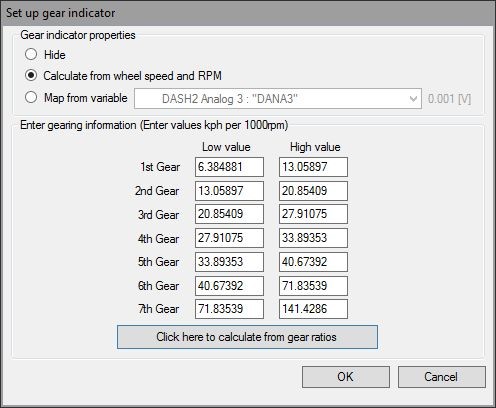

An easy way to calculate this values if the gear ratios and final drive ratio are known is to click on 'Click here to calculate from gear ratios' and then fill in the boxes:

This will populate the table automatically. It is important that the rolling circumference of the wheel is of the driven wheel.

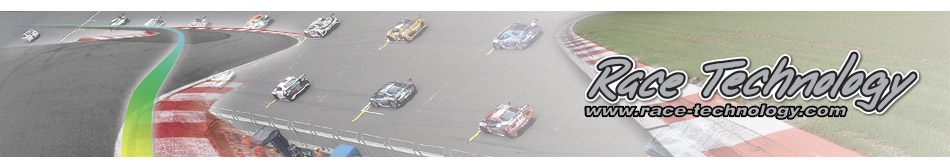

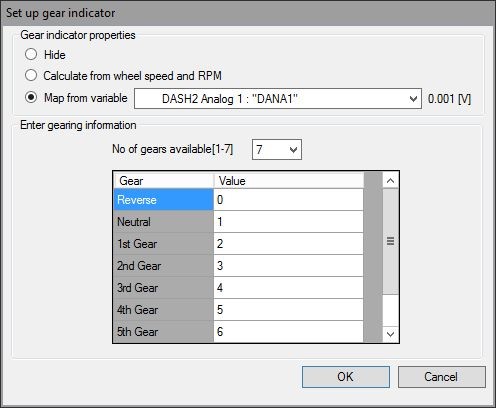

Map from variable

In some cases, where a gearbox has a gear position sensor with a voltage output or an ECU outputs the current gear information which can be read over the RS232 port, it is possible to get the gear information more directly.

The number of forward gears must be set and then the values corresponding to each gear are set in the table. The DASH2 will display the value which the incoming value is closest to. In the above example, a sensor is attached to one of the internal analogue inputs (number 3) which is shown to have a native resolution of 0.001v. Note that the values on here will be affected by any scaling applied to the internal analogue inputs in the Analogue inputs configuration section.

The gear variable can be mapped to any of the four built in analogue inputs, or to any Auxiliary channels from the RS232 port.